Description

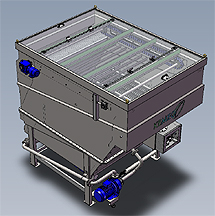

The Deltec serie is designed to treat the wastewater using the Kemeo Platepack System. The Kemeo Platepack System multiplies the separation surface for effective separation, making it possible to treat a large amount of wastewater on a small footprint. The solids are collected in the sludge thickener and transported to the sludge cone with a low friction scraper system. The sludge can be discharged with the sludge pump for thickening or discharge.

The Deltec+ flotation unit is equipped with a sludge conveyor for discharge of heavy solids.

Features & Benefits

• Very compact design, small footprint compared to capacity.

• Kemeo Platepack System for optimum separation performance.

• Low maintenance through low friction skimmer system.

• Efficient sludge discharge system by gravity.

• Efficient saturated water supply system.

• Completely manufactured out of stainless steel.

• Units up to 150 m3/h are suitable for transport in a sea container.

Common DAF Applications

• Dairy Plants: Essential for milk processing facilities, our DAF unit efficiently removes fats, oils, grease, total suspended solids, and other contaminants from dairy wastewater.

• Food processing plants: Effectively eliminates fats, oils, and grease from wastewater.

• Oil Refineries: Separates oil from water to improve wastewater quality.

• Chemical plants: Removes contaminants to ensure compliance with discharge regulations.

• Mines: Extracts solids from mine drainage and mineral processing effluents.

• Paper Mills: Recovers fibers and removes ink for improved wastewater management.

• Textile / Leather Industries: Eliminates color and contaminants from wastewater.

Contact us

Looking for a DAF Solution?

For any questions about our Dissolved Air Flotation solutions, please fill out the contact form below and our team of experts will get back to you shortly.