Less Maintenance

Sturdy & Efficient

Less Polymer Consumption

Description

In sludge dehydration, Vitone Eco’s decanters are recognized for their durability, stability, and ease of installation. They can handle a lot of sludge while using low energy and flocculants. Vitone decanters excel at reducing disposal costs by maximizing the concentration of dry substance.

Features & Benefits

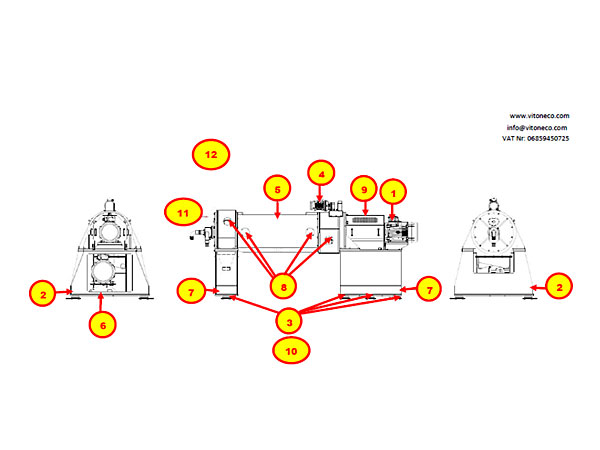

1. In-Line Scroll Motor

• The scroll motor features direct transmission, eliminating the need for pulley-belt transmission. It reduces maintenance, lower noise levels, and enhance the precision of differential speed regulation.

2. Wider Bases

• Large support surface to enhance stability and further diminish vibrations

3. Additional Anti-Vibration Supports

• Anti-vibration supports to further reduce vibrations.

4. Sludge Scraper Motor Positioned on Top of the Decanter

• Placing the sludge scraper motor on top improves the continuous cleaning of the solid discharge room during operation.

5. Thick Tunnel-Type Body

• The casing features a tubular structure, allowing for screw extraction without the need to remove the entire bowl.

6. Oscillating Bases

• Motors are supported by oscillating bases, which eliminate the vibrations typically caused by motor and transmission belt tension.

7. Built-In Supports

• With included supports, there’s no need for additional foundation installation.

8. Point of Access

• Points of access for quick service and maintenance.

9. Gear Box

• High torque and spare parts always available.

10. V-Tronic Software

• Energy Saving and User Friendly PLC

11. Turbo Mixer & Accelerator

• The Turbo Mixer enables dynamic mixing of inlet sludge and polymer using centrifugal force, resulting in minimal polymer consumption.

• The Accelerator allows for the introduction of the mixed sludge-polymer into the bowl using centrifugal force, which ensures fully clarified and clean results.

11. High Quality

• Low and economical maintenance

• Service and Spares available in USA

Products

VZERO

• Bowl Diameter: 9.5’’

• Bowl Motor: 14.7hp

• Scroll Motor: 5.3hp (Generator)

• Sludge Scraper Motor: 0.2hp

V2

• Bowl Diameter: 13.5’’

• Bowl Motor: 29.5hp

• Scroll Motor: 14.7hp (Generator)

• Sludge Scraper Motor: 1/2hp

V4

• Bowl Diameter: 18’’

• Bowl Motor: 60hp

• Scroll Motor: 40hp (Generator)

• Sludge Scraper Motor: 1hp

V5

• Bowl Diameter: 18’’

• Bowl Motor: 73.7hp

• Scroll Motor: 66hp (Generator)

• Sludge Scraper Motor: 1hp

V7

• Bowl Diameter: 21.6’’

• Bowl Motor: 100hp

• Scroll Motor: 73.7hp (Generator)

• Sludge Scraper Motor: 2hp

Applications

Contact us

Looking for a Sludge Solution?

For any questions about our sludge solutions, please fill out the contact form below and our team of experts will get back to you shortly.