Screentec

The Pump Station Bar Screen

• #1 Solution to protect pumps from clogging.

• Permanently remove wipes and other debris.

• Stops, collects, removes debris.

• Protects pumps from clogging.

• No more manual cleaning.

• Vertical, retrofits any structure.

• No submerged mechanical parts.

• User friendly.

• Fast return on investment.

• Low, economical maintenance.

• Low energy consumption.

Save money, improve process, and increase safety with Screentec

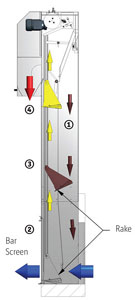

Bar Screen Description

A bar screen is a filter system designed to to remove objects such as rags, wipes and plastics and protect pumps from clogging. It is the first level of filtration used by wastewater treatment plants.

Our innovative wastewater bar screen Screentec is a mechanical vertical bar screen specifically designed to remove objects such as rags, wipes and plastics, from wastewater and protect pumps from clogging. It is the first line of defense used by wastewater treatment plants or collection system. Thanks to its unique vertical design, it can retrofit any Headworks, pump stations, lift stations, wet wells and manholes. It protects pumps from rags, wipes, plastics and other solids. It also prevents pumps from clogging up, extends their life cycle and improves the quality of wastewater treatment.

Screentec fits into narrow and deep structures, avoiding costly structural changes. It does not have any moving parts under grade level, providing easy and safe maintenance for the operational staff.

Watch the bar screen video above to learn more about Screentec.

Features & Benefits of Our Bar Screen

• Flow: 0.01mgd to 80mgd

• Depth: 4’ to 100’

• Width: 12’’ to 9’

1. Vertical Design

With a 90° installation angle, Screentec can retrofit any wastewater structure, up to 100′ deep.

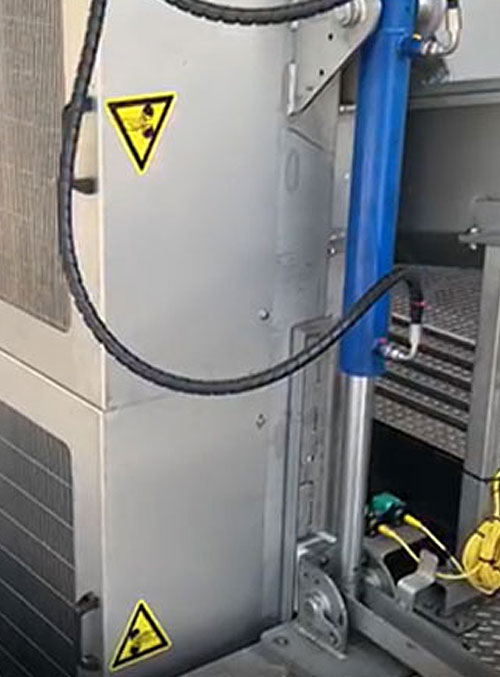

2. Minimal & Easy Maintenance.

Screentec does not have moving parts at the bottom of the frame. Weekly maintenance consists only of a visual check of the top section of the frame. Grade level access via the secure hood minimizes operator time, risk, and expense.

3. Odor Control

The frame of the vertical bar screen is completely enclosed. Adding a washer-compactor with a bagger system, such as Compactec, maintains total odor control. Screentec can be installed in residential areas

Design Guidelines

• Flow: 0.01mgd to 80mgd

• Depth: 4’ to 100’

• Width: 12’’ to 9’

• Bar spacing from 3/8’’

• Installation angle: 90°

• Front or Back Cleaning

• 304 or 316 Stainless Steel

• Lifting capacity up to 1,100lb

• Touch Screen Control Panel

• Absorbed power: from ¾hp (0.56KW)

• Voltage: custom to site availability – 3φ required

Products

Options Available

————————— Easy lift System —————————–

Applications

• Lift and Pump Stations.

• Wet Wells.

• Jails and Prisons.

• Headworks.

• Casinos & Hotels.

• Assisted Living Residences.

• Hospitals.

• Food Processing.

Material caught with Screentec

Grease Block Video – Chesapeake Beach, MD

Testimonials

“Only $800 maintenance in 10 years with Screentec!”

MENDOCINO, CA

“Aqualitec’s Screentec Bar Screen saves $500,000 a Year in pumps maintenance.”

UKIAH, CA

“75% Solids Reduction at the plant.”

SUN CITY, ARIZONA

Mendocino, CA – Video Testimonial

Ukiah, CA – Video Testimonial

Contact Us

Looking for a Screening Solution?

For any questions about our wastewater treatment solutions, please fill out the contact form below and our team of experts will get back to you shortly.