Wash Press

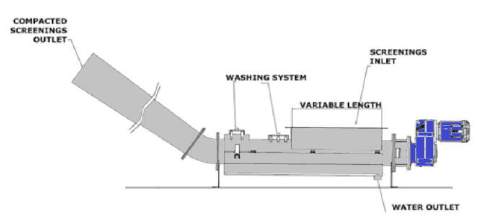

Washtec is a heavy duty automatic washer/compactor screw equipment. This innovative system is designed to effectively clean and compact screenings.

Upon discharge of debris into the WASHTEC, the equipment initiates cleaning and compacting cycles. The robust screw mechanism continuously pushes the debris into the compacting pipe, while the washing ramp efficiently cleans the debris and reduces organic matter. Once the debris is thoroughly compacted and dried within the pipe, it is conveniently discharged into a dumpster for disposal.

• Reliable.

• High performance.

• Fast return on investment.

• Low, economical maintenance.

• Low energy consumption.

Washtec will help optimizing the reduction of solid waste while sending organic back to the treatment.

Description

OPERATING MODE

The screenings are propelled forward by a heavy duty slow rotating screw while wash water is introduced in the wash/press zone. In this zone, dissolved materials and water are pressed out and returned to the wastewater treatment process.

The control system adjusts the working cycle based on the composition of the screenings.

The press mechanism transports the washed and pressed screenings through a tubular pipe system.

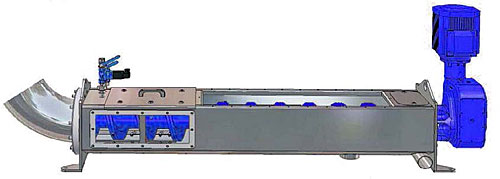

The design of the Washtec includes double troughs, providing exceptional resistance to torque during heavy operations involving screenings with high DS content. This robust “torque resistance” capability allows for a larger inlet opening to accommodate such screenings.

Features & Benefits

1. Mechanism

A heavy-duty screw continually pushes the debris into the compacting pipe, while a washing ramp effectively cleans the debris and removes organic matter. Once the debris is compacted and dried within the pipe, it is discharged into a dumpster.

The screenings are conveyed and pass through the washing zone (1) using the screw mechanism. In this zone, they undergo washing, and organic materials are removed.

Next, the screw continues conveying and pushing the screenings into the rinsing zone (2).

2. Spray Bar System, Maximum Organics Back In The Process

To enhance the removal of organic material from debris and reintroduce it back into the wastewater process, the Spray Bar System features two spray bars. This dual configuration maximizes the amount of organic material that can be effectively captured and returned to the WTP process.

3. Volume Reduction

After the screenings enter the pipe, they undergo compaction as a result of the pipe’s tubular elbow shape. As the screw continues to operate, the screenings further compact inside the pipe. Ultimately, the compacted screenings are efficiently discharged into a dumpster.

• Dry solid concentration greater than 45%

• Volume reduction greater than 70%

• Capacity: 25,000gallon/day

• Water: Non potable but clean water

• Water: 2 or 3 washing cycles/hour – cycle is 30 to 60s

• Water: Max 20 gal/hour

• Water pressure: min 87psi

• 304 or 316 Stainless Steel

• Absorbed power: 7hp (5.22KW)

• Voltage: custom to site availability – 3φ required

Applications

Contact Us

Looking for a Screening Solution?

For any questions about our wastewater treatment solutions, please fill out the contact form below and our team of experts will get back to you shortly.