Bar screens are vital components in wastewater treatment plants, serving as the first line of defense in the process. They play a key role in protecting downstream equipment and ensuring the smooth operation of treatment facilities.

What Are Bar Screens?

Bar screens are like big filtration equipment designed to remove solid and inorganic debris from wastewater. Typically, it can be made of a perforated plate or a screen with rectangular or trapezoidal bars, the diameter of the holes or the spacing between the bars determines the size of particles that can pass through. By blocking, collecting and removing solid waste, bar screens protect equipment from clogs and damage, reduce maintenance costs, and enhance the efficiency of the overall treatment process.

As the initial step in wastewater management, bar screens prevent operational disruptions, extend the lifespan of downstream systems, and help facilities comply with environmental regulations.

Types of Bar Screens and Their Applications

There are three primary types of bar screens, each suited for specific applications and budgets:

Manual Bar Screens

- Best for low-flow, non-continuous systems.

- Cost-effective but require frequent manual cleaning and maintenance.

- Ideal for smaller facilities with limited budgets.

Automatic and Mechanical Bar Screens

- Fully automated, ideal for medium andlarge-scale facilities.

- Equipped with self-cleaning mechanisms, minimizing manual labor.

- Highly efficient in handling high volumes of debris.

Selecting the right bar screen depends on factors like flow rate, debris volume, budget, and manpower availability. Proper installation and maintenance are essential to maximize performance and cost-effectiveness.

Installation and Maintenance of Bar Screens

Proper installation is critical for ensuring the functionality of bar screens. The setup must align with the facility’s needs and site conditions.

Maintenance is equally important for preventing equipment failure and ensuring long-term reliability. Key maintenance tasks include:

- Routine Inspections: Daily or weekly visual inspection helps identifies wear and tear on mechanical parts.

- Cleaning as needed: upon routine inspection check if any cleaning required, it can prevents blockages and ensures smooth water flow.

A proactive maintenance schedule reduces downtime and prolongs the lifespan of bar screens.

Innovations and the Future of Bar Screen Technology

Bar screen technology is rapidly evolving to enhance durability, efficiency, and integration with other wastewater treatment processes. Innovations include:

- Advanced Materials: Improving durability and reducing maintenance needs.

- Automation: Enabling real-time monitoring and reducing downtime.

- Integrated Systems: Offering holistic solutions for improved wastewtaer management.

These advancements not only optimize operations but also support sustainability and regulatory compliance.

The Value of Bar Screens in Waste Management

Bar screens are indispensable in modern wastewater treatment. By protecting equipment, improving efficiency, and supporting environmental compliance, they ensure the success of wastewater management systems.

Investing in advanced bar screen technology is a strategic decision that promotes sustainability, reduces operational costs, and enhances system reliability.

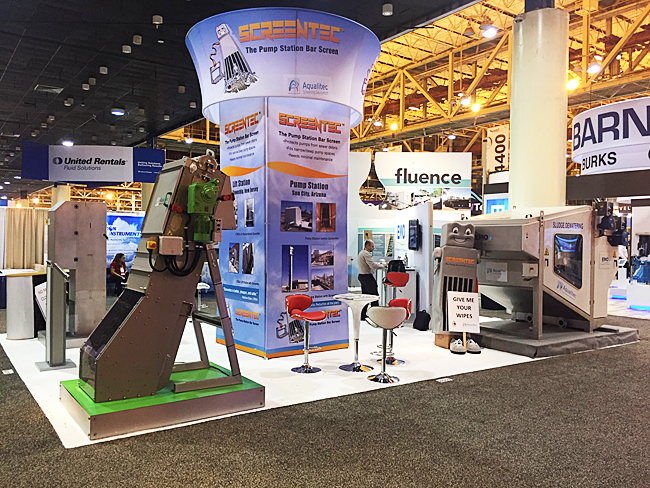

Aqualitec’s Innovative Bar Screen Protects Pumps From Debris

Aqualitec’s bar screen Screentec is a mechanical vertical bar screen specifically designed to remove objects such as rags, wipes and plastics, from wastewater and protect pumps from clogging. It is the first line of defense used by wastewater treatment plants or collection system.

Thanks to its unique vertical design, it can retrofit any Headworks, pump stations, lift stations, wet wells and manholes. It protects pumps from rags, wipes, plastics and other solids. It also prevents pumps from clogging up, extends their life cycle and improves the quality of wastewater treatment.

Looking for a Bar Screen Solution?

Call 855-650-2214 or email us here