Internally Fed Drum Screen

Drumtec is a rotary drum screen that has been specifically designed for heavy pretreatment applications, including municipal wastewater, mud thickening, septic receiving stations, and food processing facilities. This product is especially well-suited for use in membrane bioreactor (MBR) treatment plants.

The Drumtec is fed internally and features a pinion-and-rack driving system. It is highly reliable, requiring minimal maintenance and little user involvement in day-to-day operation.

• Innovative.

• Sturdy.

• Reliable.

• No Sprockets or chain system.

• Smoothly conveys debris.

• Jam-less design.

• Fast return on investment.

• Low, economical maintenance.

• Low energy consumption.

Raketec will help you save money while improving process and working conditions.

Description

OPERATING MODE

Drumtec is an internally fed rotary drum screen that operates by dividing wastewater evenly with a deflector as it flows into the drum.

The flow then passes through a perforated plate, which screens solids from the water.

Waste materials are transported by a large flight auger to the end of the drum, where they are emptied into either a built-in washer/compactor or directly into a dumpster.

Features & Benefits

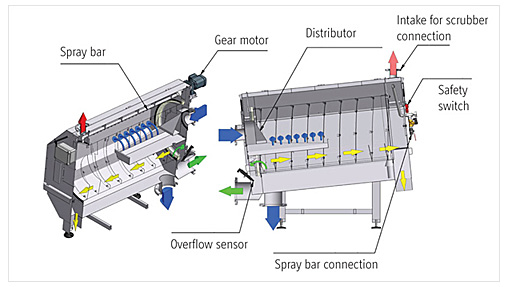

1. Simple and Reliable Driving System

It consists of a pinion-and-rack system that is driven by a gear motor, causing the drum to rotate. This mechanism is constructed of HDPE (High Density Polyethylene) and does not require any maintenance.

To ensure stability during rotation, the drum is supported by oversized trunnions.

2. High Capture Rate

Drumtec effectively captures a wide variety of debris, including rocks, grits, organics, wipes, rags, fibers, and other materials. The perforated plate used in the system has a high capture rate, with the ability to screen materials as small as 800 microns.

This makes Drumtec an excellent solution for fine screening, particularly when used in conjunction with a MBR system.

3. Safe and Easy Access

Each side of the drum cover is equipped with a lift handle for easy opening. To assist with this process, a hydraulic mechanism is in place, allowing a single operator to safely open the cover.

Weekly maintenance of the system is minimal and only consists of visually inspecting the drum and the spray bar nozzles. If necessary, the nozzles can be easily removed for cleaning or replacement.

5. All-in-one equipment

To achieve a comprehensive screening treatment process, a built-in washer/compactor can be positioned directly at the discharge chute.

Design Guidelines

• Drum length: 3’ to 10’

• Drum Diameter: from 2.6’ to 5’

• Perforated plate from 1mm (1/32’’)

• Wedge wire from 250 to 750 microns

• 304 or 316 Stainless Steel

• Touch Screen Control Panel

• Absorbed power: ¾hp (0.56KW)

• Voltage: custom to site availability – 3φ required

Applications

Contact Us

For any questions about our wastewater treatment solutions, please fill out the contact form below and our team of experts will get back to you shortly.